Safety Survey

Safety Survey

Safety Survey

Training

Training

Training

Empower your team with the essential skills and knowledge to maintain workplace safety with our comprehensive Racking Safety Awareness and Training Services. Invest in your team and confidence today – a step towards a safer, more efficient workplace.

Empower your team with the essential skills and knowledge to maintain workplace safety with our comprehensive Racking Safety Awareness and Training Services. Invest in your team and confidence today – a step towards a safer, more efficient workplace.

Empower your team with the essential skills and knowledge to maintain workplace safety with our comprehensive Racking Safety Awareness and Training Services. Invest in your team and confidence today – a step towards a safer, more efficient workplace.

Racking Safety Awareness

Rack damage could result in a collapse if allowed to accumulate. The risk of collapse can be minimised by regular damage racking inspection and reporting followed by prompt repair. Internal weekly/monthly damage assessments can be carried out by suitably trained employees working to a formal inspection programme. These in-house seminars are designed to empower your staff to carry out these checks, which should be complimented by a formal annual external pallet racking safety inspection.

Topics include:

Damage assessment

Damage causes & effects

Damage reduction/prevention

Responsibilities- corporate & individual

Legal responsibilities

Fork truck/Racking interface etc…

Who should attend?

Warehouse Managers

Health & Safety Officers

Warehouse supervisors

FLT drivers etc…

What will you gain?

Awareness of basic legal responsibilities

Damage assessment criteria

Assessment & survey frequency

Rack Maintenance Training

When racking inspections aren't carried out and racking becomes damaged by fork lift truck impact, prompt reporting of damage and prompt repair is essential as damage could result in a collapse if allowed to accumulate.

This in-house training programme is designed to empower suitably qualified maintenance personnel to carry out simple basic maintenance to damaged racking.

It must be borne in mind that racking is a load-bearing structure and correct maintenance is imperative to maintain the integrity and stability of the structure. It is also suggested that more extensive refurbishment and remedial work is left to professional installation crews.

This Rack Maintenance Training illustrates safe methods for replacement of damaged racking components and shows the most common types of damage. The course also discusses the skills needed by operatives tasked with the maintenance of racking, what is permissible and where to "draw the line" it also briefly discusses the potential insurance and legal issues.

Who should attend?

Maintenance Managers

Qualified fitters

Maintenance Engineers

Etc

Access Equipment Training

We can provide Operator Training on a wide range of powered access equipment including:

Scissor lift (electric & diesel)

Self Propelled Boom

Vehicle Mounted Platform

Most courses are single day duration and can be carried out on your own site if required (subject to facilities). All training is carried out to standards by qualified instructors and will include:

Basic harness usage & inspection

Operator Responsibilities

Current legislation

The prime concern must be the safe operation of any MEWP (Mobile elevating work platform) and the safety of operatives and of other persons working in immediate or adjacent areas. Machines must be operated within the recommended limits and according to the manufacturers instructions. Machines must be maintained and operated correctly and must not be misused, overloaded or interfered with in any way.

As "Lifting Equipment", all MEWPs fall under PUWER & LOLER legislation.

We can provide Operator Training on a wide range of powered access equipment including:

Scissor lift (electric & diesel)

Self Propelled Boom

Vehicle Mounted Platform

Most courses are single day duration and can be carried out on your own site if required (subject to facilities). All training is carried out to standards by qualified instructors and will include:

Basic harness usage & inspection

Operator Responsibilities

Current legislation

The prime concern must be the safe operation of any MEWP (Mobile elevating work platform) and the safety of operatives and of other persons working in immediate or adjacent areas. Machines must be operated within the recommended limits and according to the manufacturers instructions. Machines must be maintained and operated correctly and must not be misused, overloaded or interfered with in any way.

As "Lifting Equipment", all MEWPs fall under PUWER & LOLER legislation.

Safety Harness Training

All personnel should be adequately trained in the use of any PPE required for the safe operation of their work. Use of a safety harness may not prevent a fall from height, but correct training in the selection, adjustment, use and maintenance of Harness and Lanyard could reduce the consequences of such a fall.

Includes:

Current Legislation

Harness selection

Lanyard selection & use

Work restraint

Work positioning

Fall restraint

Harness & lanyard inspection

Rescue plans

Suspension trauma

Totally independent & impartial

Forklift Truck Training

Courses offered:

FLT operator, Beginner - 5 Days

FLT operator, Experienced - 2 Days

FLT operator, Refresher - 1 Day

Conversion counterbalance to reach - 2 Days

Conversion reach to counterbalance - 1 Day

Includes:

Current legislation

Operator responsibilities

Safe operation

The prime concern must be the safe operation of any fork lift truck and the safety of operatives and of other persons working in immediate or adjacent areas. Machines must be operated within the recommended limits and according to the manufacturers instructions. Machines must be maintained an operated correctly and must not be misused, overloaded or interfered with in any way.

As "Lifting Equipment", all Fork Lift trucks fall under PUWER & LOLER legislation and must be regularly inspected. Operators should also appreciate the dangers to themselves and others from damaged racking and report any damage to senior management for assessment.

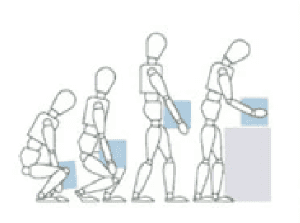

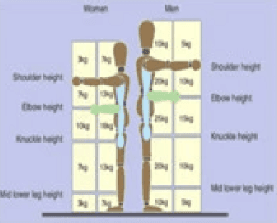

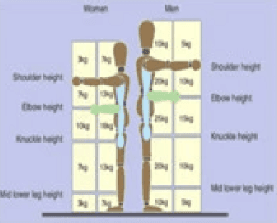

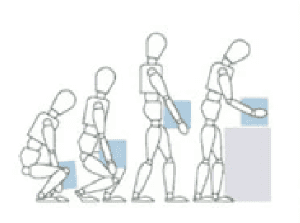

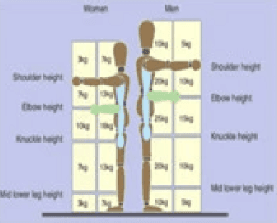

Manual Handling Training

As an employer, you must protect your workers from the risk of injury from hazardous manual handling in the workplace. Manual handling means transporting or supporting a load by hand or bodily force. It includes lifting, putting down, pushing, pulling, carrying or moving loads.

Racking Safety Awareness

Rack damage could result in a collapse if allowed to accumulate. The risk of collapse can be minimised by regular damage racking inspection and reporting followed by prompt repair. Internal weekly/monthly damage assessments can be carried out by suitably trained employees working to a formal inspection programme. These in-house seminars are designed to empower your staff to carry out these checks, which should be complimented by a formal annual external pallet racking safety inspection.

Topics include:

Damage assessment

Damage causes & effects

Damage reduction/prevention

Responsibilities- corporate & individual

Legal responsibilities

Fork truck/Racking interface etc…

Who should attend?

Warehouse Managers

Health & Safety Officers

Warehouse supervisors

FLT drivers etc…

What will you gain?

Awareness of basic legal responsibilities

Damage assessment criteria

Assessment & survey frequency

Racking Safety Awareness

Rack damage could result in a collapse if allowed to accumulate. The risk of collapse can be minimised by regular damage racking inspection and reporting followed by prompt repair. Internal weekly/monthly damage assessments can be carried out by suitably trained employees working to a formal inspection programme. These in-house seminars are designed to empower your staff to carry out these checks, which should be complimented by a formal annual external pallet racking safety inspection.

Topics include:

Damage assessment

Damage causes & effects

Damage reduction/prevention

Responsibilities- corporate & individual

Legal responsibilities

Fork truck/Racking interface etc…

Who should attend?

Warehouse Managers

Health & Safety Officers

Warehouse supervisors

FLT drivers etc…

What will you gain?

Awareness of basic legal responsibilities

Damage assessment criteria

Assessment & survey frequency

Rack Maintenance Training

When racking inspections aren't carried out and racking becomes damaged by fork lift truck impact, prompt reporting of damage and prompt repair is essential as damage could result in a collapse if allowed to accumulate.

This in-house training programme is designed to empower suitably qualified maintenance personnel to carry out simple basic maintenance to damaged racking.

It must be borne in mind that racking is a load-bearing structure and correct maintenance is imperative to maintain the integrity and stability of the structure. It is also suggested that more extensive refurbishment and remedial work is left to professional installation crews.

This Rack Maintenance Training illustrates safe methods for replacement of damaged racking components and shows the most common types of damage. The course also discusses the skills needed by operatives tasked with the maintenance of racking, what is permissible and where to "draw the line" it also briefly discusses the potential insurance and legal issues.

Who should attend?

Maintenance Managers

Qualified fitters

Maintenance Engineers

Etc

Access Equipment Training

We can provide Operator Training on a wide range of powered access equipment including:

Scissor lift (electric & diesel)

Self Propelled Boom

Vehicle Mounted Platform

Most courses are single day duration and can be carried out on your own site if required (subject to facilities). All training is carried out to standards by qualified instructors and will include:

Basic harness usage & inspection

Operator Responsibilities

Current legislation

The prime concern must be the safe operation of any MEWP (Mobile elevating work platform) and the safety of operatives and of other persons working in immediate or adjacent areas. Machines must be operated within the recommended limits and according to the manufacturers instructions. Machines must be maintained and operated correctly and must not be misused, overloaded or interfered with in any way.

As "Lifting Equipment", all MEWPs fall under PUWER & LOLER legislation.

Safety Harness Training

All personnel should be adequately trained in the use of any PPE required for the safe operation of their work. Use of a safety harness may not prevent a fall from height, but correct training in the selection, adjustment, use and maintenance of Harness and Lanyard could reduce the consequences of such a fall.

Includes:

Current Legislation

Harness selection

Lanyard selection & use

Work restraint

Work positioning

Fall restraint

Harness & lanyard inspection

Rescue plans

Suspension trauma

Totally independent & impartial

Forklift Truck Training

Courses offered:

FLT operator, Beginner - 5 Days

FLT operator, Experienced - 2 Days

FLT operator, Refresher - 1 Day

Conversion counterbalance to reach - 2 Days

Conversion reach to counterbalance - 1 Day

Includes:

Current legislation

Operator responsibilities

Safe operation

The prime concern must be the safe operation of any fork lift truck and the safety of operatives and of other persons working in immediate or adjacent areas. Machines must be operated within the recommended limits and according to the manufacturers instructions. Machines must be maintained an operated correctly and must not be misused, overloaded or interfered with in any way.

As "Lifting Equipment", all Fork Lift trucks fall under PUWER & LOLER legislation and must be regularly inspected. Operators should also appreciate the dangers to themselves and others from damaged racking and report any damage to senior management for assessment.

Manual Handling Training

As an employer, you must protect your workers from the risk of injury from hazardous manual handling in the workplace. Manual handling means transporting or supporting a load by hand or bodily force. It includes lifting, putting down, pushing, pulling, carrying or moving loads.

Rack Maintenance Training

When racking inspections aren't carried out and racking becomes damaged by fork lift truck impact, prompt reporting of damage and prompt repair is essential as damage could result in a collapse if allowed to accumulate.

This in-house training programme is designed to empower suitably qualified maintenance personnel to carry out simple basic maintenance to damaged racking.

It must be borne in mind that racking is a load-bearing structure and correct maintenance is imperative to maintain the integrity and stability of the structure. It is also suggested that more extensive refurbishment and remedial work is left to professional installation crews.

This Rack Maintenance Training illustrates safe methods for replacement of damaged racking components and shows the most common types of damage. The course also discusses the skills needed by operatives tasked with the maintenance of racking, what is permissible and where to "draw the line" it also briefly discusses the potential insurance and legal issues.

Who should attend?

Maintenance Managers

Qualified fitters

Maintenance Engineers

Etc

Access Equipment Training

We can provide Operator Training on a wide range of powered access equipment including:

Scissor lift (electric & diesel)

Self Propelled Boom

Vehicle Mounted Platform

Most courses are single day duration and can be carried out on your own site if required (subject to facilities). All training is carried out to standards by qualified instructors and will include:

Basic harness usage & inspection

Operator Responsibilities

Current legislation

The prime concern must be the safe operation of any MEWP (Mobile elevating work platform) and the safety of operatives and of other persons working in immediate or adjacent areas. Machines must be operated within the recommended limits and according to the manufacturers instructions. Machines must be maintained and operated correctly and must not be misused, overloaded or interfered with in any way.

As "Lifting Equipment", all MEWPs fall under PUWER & LOLER legislation.

Safety Harness Training

All personnel should be adequately trained in the use of any PPE required for the safe operation of their work. Use of a safety harness may not prevent a fall from height, but correct training in the selection, adjustment, use and maintenance of Harness and Lanyard could reduce the consequences of such a fall.

Includes:

Current Legislation

Harness selection

Lanyard selection & use

Work restraint

Work positioning

Fall restraint

Harness & lanyard inspection

Rescue plans

Suspension trauma

Totally independent & impartial

Forklift Truck Training

Courses offered:

FLT operator, Beginner - 5 Days

FLT operator, Experienced - 2 Days

FLT operator, Refresher - 1 Day

Conversion counterbalance to reach - 2 Days

Conversion reach to counterbalance - 1 Day

Includes:

Current legislation

Operator responsibilities

Safe operation

The prime concern must be the safe operation of any fork lift truck and the safety of operatives and of other persons working in immediate or adjacent areas. Machines must be operated within the recommended limits and according to the manufacturers instructions. Machines must be maintained an operated correctly and must not be misused, overloaded or interfered with in any way.

As "Lifting Equipment", all Fork Lift trucks fall under PUWER & LOLER legislation and must be regularly inspected. Operators should also appreciate the dangers to themselves and others from damaged racking and report any damage to senior management for assessment.

Manual Handling Training

As an employer, you must protect your workers from the risk of injury from hazardous manual handling in the workplace. Manual handling means transporting or supporting a load by hand or bodily force. It includes lifting, putting down, pushing, pulling, carrying or moving loads.

FAQs

What services does Safety Survey offer as warehouse safety specialists?

Why is racking inspection important for my company?

What types of inspections and training services are available?

How can Safety Survey help with compliance with legal requirements and insurers?

When should I consider a racking inspection according to the SEMA code of practice?

Can Safety Survey assist in setting up internal racking checks?

What specialist services does Safety Survey provide?

How often should racking inspections be conducted to ensure safety?

How can I benefit from Safety Survey's expert racking inspections?

How can I schedule an inspection or training session with Safety Survey?

What services does Safety Survey offer as warehouse safety specialists?

Why is racking inspection important for my company?

What types of inspections and training services are available?

How can Safety Survey help with compliance with legal requirements and insurers?

When should I consider a racking inspection according to the SEMA code of practice?

Can Safety Survey assist in setting up internal racking checks?

What specialist services does Safety Survey provide?

How often should racking inspections be conducted to ensure safety?

How can I benefit from Safety Survey's expert racking inspections?

How can I schedule an inspection or training session with Safety Survey?

What services does Safety Survey offer as warehouse safety specialists?

Why is racking inspection important for my company?

What types of inspections and training services are available?

How can Safety Survey help with compliance with legal requirements and insurers?

When should I consider a racking inspection according to the SEMA code of practice?

Can Safety Survey assist in setting up internal racking checks?

What specialist services does Safety Survey provide?

How often should racking inspections be conducted to ensure safety?

How can I benefit from Safety Survey's expert racking inspections?

How can I schedule an inspection or training session with Safety Survey?